SealScope: Seal Inspection and Process Monitoring for Stand-up Pouches

Why You Need to Know About SealScope™ And Process Monitoring

As a business owner, you know that the quality of your seals determines the quality of your product. A leaking pouch can lead to a number of detrimental outcomes. Seals that are not airtight can cause reduced shelf life and consumer health hazards. These packages can also contaminate other packages and damage your brand image. Not to mention, poor quality seals could lead to a costly recall for your company.

Let’s discuss how adding SealScope™ inspection and process monitoring technology to your pouch packaging line can save and make you money, by improving your outgoing product quality and increasing your effective line output.

What is SealScope™?

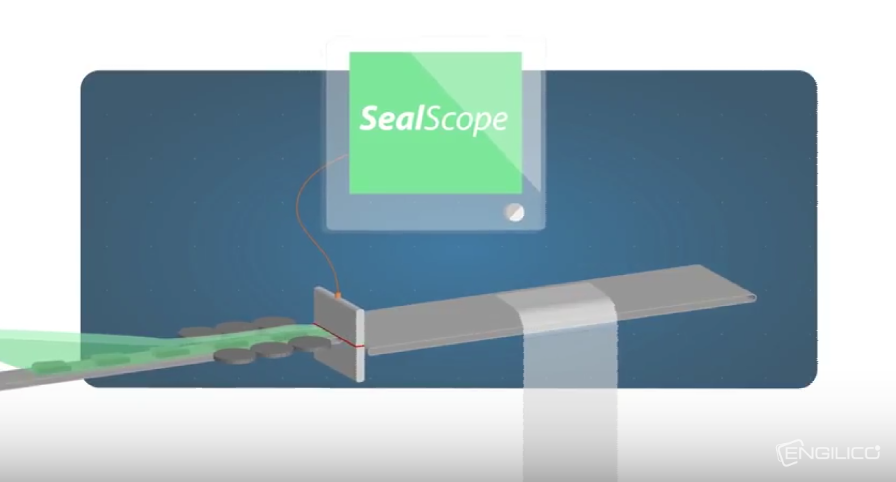

SealScope™, brought to us by Engilico, is the first in-line seal inspection and monitoring tool that will not slow down your production. Using sensors on the sealing jaws combined with intelligent software, SealScope™ detects and rejects defective packages. These packages could have wrinkled seals or product in seal.

Additionally, it also continuously monitors your sealing process and notifies you in case of drift. Dirt accumulation on the sealing jaws, wear on moving parts, and clogging filling nozzles can all lead to drift.

For a full visual experience, watch the video below!

SealScope™ can both be retrofitted to your existing packaging equipment and pre-installed as an option on new machines.

Benefits of Using SealScope™

Rejecting compromised packages before they leave the factory could be a life saver for your business. This feature, ensures the quality of your outgoing product and reduces packaging costs.

Using SealScope™ for Process monitoring will allow you to detect machine drift in early stages so you can take action sooner. These warnings are comparable to a check engine or change oil light in your car. By keeping your process within its optimal settings, you will be able to effectively produce more, without sacrificing quality.

For Lutèce, a Dutch company in the mushroom market, SealScope™ has reduced the number of defective packages leaving the factory by over 90%! In addition, they were able to increase productivity with more than 20%, thanks to SealScope™.

Want to Learn More?

If you use stand-up pouches in your production line, there is no doubt that Engilico’s SealScope™ will be a game changing addition to your packing line. Less waste and a higher quality product on the shelves will easily save you money and represent your business in a brighter light! Reach out to us here at K-Flex Packaging Systems. We are happy to tell you more about the benefits of SealScope™ and get you quoted today!